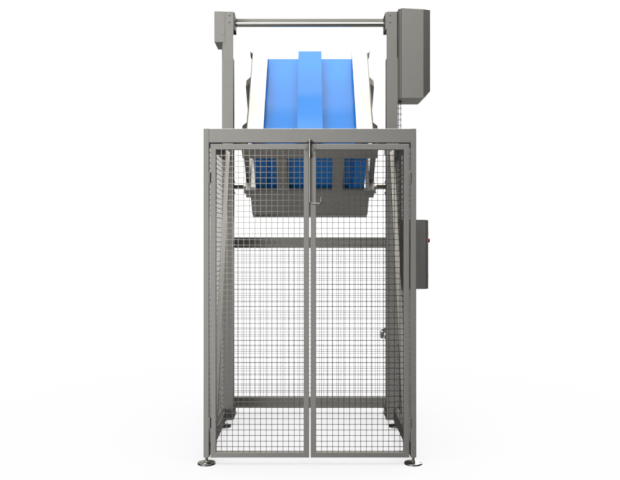

Nimo-KG SK 800 MK2 Double column lift

Overview

The SK 800 MK2 lifting and tipping device, commonly referred to as a twin column lift, is a versatile solution primarily used within the food industry. Its primary function is to elevate and tilt standard 600-liter EURO-containers, facilitating various processes such as forming, filling, grinding, mixing, and more. This adaptable twin column lift can also be tailored to accommodate barrels, different large containers, or other specific industrial applications, extending its utility to sectors like chemicals, pharmaceuticals, and engineering workshops.

Designed with meticulous attention to ergonomic principles, the twin column lift prioritizes operator safety while enhancing overall production efficiency. Its ergonomic features minimize the risk of personnel injury, aligning with industry standards and best practices.

Design and function

The twin column lift comprises two main components: the main stand and the lifting frame. The stand consists of two columns constructed from plates and fully welded single hollow sections. The bottom frame is equipped with four feet for securing the machine to the floor. The lifting frame is primarily constructed from fully welded single hollow sections and moves within the columns. Vertical motion is achieved through an electro-mechanical system using either a roller chain or belt.

To ensure safety, the container to be tipped is positioned within the lifting frame, which features a retaining mechanism to secure the container in place. The twin column lift is driven by an electric gearbox motor with a brake. Operation is controlled via electrical push buttons, including an emergency stop button. The tipping process begins when the upper follower rollers of the lifting frame engage with the tipping curves, while simultaneously, the lower rollers continue to ascend within the columns.

For safety measures, the machine is equipped with a safety cage featuring electrically interlocked doors to prevent accidents.

General Points

The twin column lift is designed in accordance with the specifications of food industry authorities and complies with CE norms: 2006/42/EC, 2006/95/EC, and 2004/108/EC, as confirmed in the declaration of conformity enclosed in the CE documentation.

The twin column lift can be supplied in various standard designs at an additional cost:

- Low-built model (SK 800 MK-L)

- Mobile on wheels or able to move sideways on a rail (SK 800 MK2-T)

- Equipped with a combined lifting frame for buggies

- Features a locking device for special containers or varying container heights

- Suitable for heavier loads (maximum 1500 kgs)

- Offers an individually designed chute

- For technical data and dimensions, please refer to separate manual sheets.

- Special offers are available upon request.

Technical Specifications

The key components of the twin column lift are expertly crafted from stainless steel (AISI 304, SS2333) that has undergone a thorough glass-bead blasting process. For stability, the bottom frame features four stainless steel feet (M20) that offer adjustable height (+25/-15 mm) and secure fastening to the floor using M16 bolts.

Ensuring safety during operation, the twin column lift is equipped with a protective cage that incorporates electrically interlocked doors, further reinforced by a spring-loaded locking mechanism for mechanical security.

Within the lift’s columns, the lifting frame glides smoothly on four high-density plastic wheels. The transmission system employs two 1″ Simplex roller chains constructed from robust steel (BS 228-1962, SMS 1613) or a belt. These chains are firmly attached to the lifting frame using stainless steel link components. (As an optional feature, both the chain and chain wheels can be manufactured from stainless steel.)

Safety features include electro-mechanical limit switches to halt vertical motion, along with a top-position safety switch. The control panel boasts electrical buttons for seamless up and down motion control, complete with an emergency stop function.

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

All our machines are custom-made

to fit your facilities

Specifications:

- Motor Type 90

- Power 1.5 kW

- Speed 1400 rpm

- Gear Design Foot B3

- Voltage / Control Voltage 400/230 V, 50 Hz / AC 24 V, 50 Hz

- Braking Torque 25 Nm

- Lifting Speed 7.1 m/min

- Operating Orientation Right (left-hand design available as an option)

- Maximum Lifting Capacity 800 kg

Markets served:

- Meat processing industry

- Food processing industry

- Chemical industry

- Pharmaceutical industry

Argentina:

Argentina:

Alfa Argentina S.A.

Barracas Capital Federal

Buenos Aires

Argentina

Tel: +54(0) 11 43012639

Web: http://www.alfaargentina.com

Australia:

Australia:

Global Machinery & Supplies

3 Albion Lane

2088 Mosman NSW

Australia

Tel: +61 29969 0370

Fax: +61 29969 0312

Web: http://www.globalms.com.au

Belarus:

Belarus:

Mirozdanie ALC

Babushkina 29/9

220024 Minsk

Belarus

Tel: +375 17 2 91 86 29

Web: http://mzd.deal.by

Belgium:

Belgium:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

E-mail: info@backsaver.nl

Web: https://www.backsaver.nl/

Canada:

Canada:

Dpec Food Solutions Inc.

6705 Tomken Rd, Unit 15

Mississauga (ON), L5T-2J6

Canada

Tel: +1 905-565-1500

Web: https://www.dpecfoodsolutions.ca

Chile:

Chile:

Alfa Chilena S.A.

Dirección: Las Américas 700

Cerrillos | Santiago | Chile

Chile

Tel: +56 (2) 288 99 000

Web: http://www.alfachilena.cl

Estonia:

Estonia:

Provitek Balti Oü

Reti tee 4

Peetri alevik

Rae vald

75312 Harjumaa

Estonia

+372 6393152

Web: http://www.provitek.fi

Finland:

Finland:

Hagson-Provitek Oy

c/o Knitter Business Park

Kutojantie 6-8

02630 Espoo

Finland

Office +358(0)9 439 307 0

Web: http://www.provitek.fi

France:

France:

Technocarne

1, route du Golf

67610 LA WANTZENAU

France

Tél. (33) 03 88 33 09 33

Fax : (33) 03 88 83 00 11

Web:http://www.technocarne.com

Germany:

Germany:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

E-mail: info@backsaver.nl

Web: https://www.backsaver.nl/

Greece:

Greece:

Vamvacas Industrial Equipment SA

Iceland:

Iceland:

Klaki stálsmiðja

Hafnarbraut 25

200 Kopavogur

Iceland

Tel: +354-554 00 00

Fax: +354-554 41 67

Web: http://www.klaki.is

Ireland:

Ireland:

Shareteq Ltd Ireland

1st Floor, 6 Lapps Quay

Cork

Ireland

T: +44-1775-710100

E: info@shareteq.com

Web: http://www.shareteq.com

Italy:

Italy:

Cavalli Meat Processing Machinery s.r.l.

Via XXV Aprile 18

43035 Felino (Parma)

Italy

tel. +39-0521-836670

fax +39-0521-837647

Web: http://www.cavallimpm.it

Japan:

Japan:

Radix Co. Ltd.

Ariake(keiwa) Bd. 3-12-16 Turumaki

154-0016 Setagaya-ku Tokyo

Japan

Tel: +81-3-5426-7183

Web: https://radix-inc.co.jp/

Latvia:

Latvia:

Regrand

26, Ganibu Dambis Str.

LV-1005 Riga

Latvia

Tel: +371 673 95339

Web: http://www.regrand.eu

Lithuania:

Lithuania:

Travalsa UAB

Vilniaus 21pšt.,p/d Nr.2762

LT-08018

Lithuania

Tel: +370 680 1077

Fax: +370 521 524 44

Moldova:

Moldova:

Tara.md Moldava Packing Site

str.T.Vladimirescu 8/1, etajul 4

Chisinau

Moldova

Tel: +373 78080914

Web: http://www.tara.md

Netherlands:

Netherlands:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

Web: https://www.backsaver.nl

New Zealand:

New Zealand:

Global Machinery & Supplies

2B Glover Street

2088 Mosman NSW

Australia

Tel: +61 29969 0370

Fax: +61 29969 0312

Web: http://www.globalms.com.au

Poland:

Poland:

Brokelmann Sp. z o.o.

56-300 Milicz

ul. Stawna 6

Poland

tel./fax +48 71 38 42 584

Web: http://www.brokelmann.pl

Slovakia:

Slovakia:

PQS s.r.o.

Stará Vajnorská 37

831 04 Bratislava

Slovakia

tel/fax. +42 12 446 33 141

Web: www.1pqs.sk

South-Africa:

South-Africa:

Gerber Fresh

Unit 2, 81 Falcon Crescent,

Capital Hill Commercial Estate,

Cr R 101 & Le Roux Drive, Midrand

South Africa

Tel +27 (0) 10 001 5222

Web: http://www.gerberfresh.co.za

Korea, Republic of:

Korea, Republic of:

Young Dong E&TS

991-4, Shinwol-dong

Yangchon-gu, Seoul

Korea

Tel: +82 2 2695 6915

Web: http://www.ydents.net

Switzerland:

Switzerland:

Max Urech AG

Lager- und Fördertechnik

Parallelstrasse 4

5606 Dintikon

Switzerland

Tel: +41 56 616 70 10

Web: http://max-urech.ch

Turkey:

Turkey:

Bemak Makina

Perpa Ticaret Merkezi A Blok

Kat:5 No:85 Okmeydanı

Şişli, İSTANBUL

Turkey

Tel: +90 212 210 55 30

Web: http://www.bemakmakina.com.tr

United Kingdom:

United Kingdom:

Shareteq Ltd

PO Box 1002

Spalding

PE11 1WE (England)

United Kingdom

Tel: +44-1775-710100

Web: http://www.shareteq.com

United States of America:

United States of America:

MID-WEST:

Premier Handling Solutions

1415 Davis Road

Elgin (IL) 60123

United States of America

Tel: +1 800-404-2311

Fax: +1 847-278-2310

http://www.phsinc.com

Can't find a reseller in your area? Please call our headquarters: +31 411 672 652

Are you interested in selling our products? Do you want to become a reseller? Make people lift smart! Please send us an e-mail: info@backsaver.nl

Polski

Polski Italiano

Italiano Svenska

Svenska Nederlands

Nederlands Deutsch

Deutsch Français

Français Español

Español Русский

Русский 日本語

日本語 한국어

한국어

Russia:

Russia: Spain:

Spain: